FCL vs LCL

You may have heard of FCL and LCL shipments if you have experience in importing and exporting your goods. In this article we will discuss the differences between FCL and LCL logistics, and also clarify their advantages and disadvantages. You will then be able to make a proper decision on the most beneficial shipping option for your business.

1. What is FCL and LCL?

FCL and LCL shipments are two common terms used in the international logistics industry for export and import cargo by sea.

– FCL = Full Container Load

– LCL = Less than Container Load – LCL = Less than Container Load – LCL = Less than Container Load – LCL = Less than Container Load – LCL = Less than Container Load – LCL = Less than Container Load – LCL = Less than Container Load – LCL = Less than Container Load

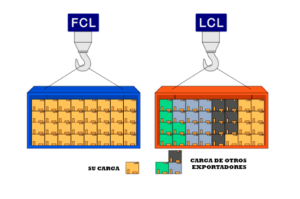

FCL logistics is a method of transporting goods in which your shipment occupies a full container (of any size). LCL logistics refers to many shipments sharing container space. It means that if your cargo does not require the capacity of a full container, it must be combined with LCL shipments from other importers and then transported inside a container. That is why LCL shipment is also known as “Consolidation” or “Bundling”.

2. Compare FCL vs LCL

Transit time

It is obvious that LCL shipment takes more time than FCL shipment due to consolidation and deconsolidation. Specifically, service companies have to bundle many shipments, sort and pack them into containers, and then arrange the transportation of the goods from the port of loading (POL) to the port of destination. During the customs clearance process, if there is a problem with a particular shipment, it can affect all importers who have cargo in that container and cause delays in deliveries. Meanwhile, FCL shipments do not need to be loaded and unloaded along with other shipments, so their transit time is usually one to two weeks faster. Shipping costs

Normally, LCL costs more than FCL per unit load. The cost of LCL is calculated primarily by volume, usually in cubic meters (CBM), which means that the more space you need, the more you pay. On a per unit basis, LCL shipping costs are expensive, as they include additional logistics and handling costs related to shipping multiple goods in one container. Freight forwarders’ LCL price quotations include:

– Pickup: the cost of picking up your goods from the warehouse or factory. – Origin: your LCL shipments must be loaded into containers along with other shipments, or consolidated, at a Container Freight Station (CFS), also called a container filler. – Main leg: the cost of the ocean voyage. – Destination: in the country of destination, LCL shipments have to stop at a CFS for deconsolidation, also known as deconsolidation. – Delivery: the cost of trucking the goods to the destination warehouse. Despite being the main leg of shipments, this cost may not be the most expensive. On the other hand, CFS costs can be high, as they involve a significant amount of machinery and labor.

. Resumen: Ventajas y desventajas de FCL frente a LCL

A partir del análisis anterior, la logística FCL parece ser más económica para los importadores, sobre todo en el contexto de la subida de los fletes marítimos en 2021, pero no puede ser ideal para todas las mercancías. A veces, el envío LCL sería una mejor opción si sus envíos son de bajo volumen (entre 2 y 13m3). The following are the main benefits and drawbacks of FCL versus LCL logistics for your reference.

FCL Logistics LCL Logistics

Advantages – Faster transit time

– Less chance of damage

– Lower price per unit

– Much lower costs than air freight – Better for shipping small loads

– Less inventory and management costs

– Lower supply risk

– Easier to find space during peak season Disadvantages – Higher inventory costs

– Expensive for small loads

– Unloading can be a hassle

– Few delivery options

– Longer transit time

– Higher cost per unit

– Delays may occur

– Increased possibility of damage

Pros and cons of FCL vs LCL

In conclusion, the choice to use between FCL vs LCL ocean shipping methods depends largely on the conditions and purposes of the consignees (importers) – including the supply of goods, the size of the consignee’s capital and quantity demanded or the characteristics of the imported goods such as their suitability for long-term inventory in large quantities.